Clutch

Find your replacement part

Why Blue Print Clutches?

Our clutches

Blue Print provides the automotive aftermarket with an exceptional offer of clutch components, including:

- Clutch Kits

- Clutch Covers

- Clutch Discs

- Release Bearings

- Flywheels

- Clutch Master Cylinders

- Clutch Slave Cylinders

- Clutch Release Forks

- Clutch Cables

SMARTFIT Clutch Kits

Blue Print offers tailor-made solutions for a professional and cost-effective repair through our SMARTFIT range. These replacement alternatives represent the best possible balance between driving comfort and cost-effectiveness. Our SMARTFIT kits for dual-mass flywheels and self-adjusting clutches are easy to install and of the highest fitting accuracy.

Why Blue Print SMARTFIT Clutch Kits?

- Range of 230 SMARTFIT clutch kits, covering more than 8,000 vehicle applications

- Conversion kits to a conventional Clutch technology - a complete, professional repair solution

- Excellent driving comfort and ‘feel’

- Easy to install, with a perfect FIT

SMARTFIT Conversion Kits for Dual-Mass Flywheels

The SMARTFIT for dual-mass flywheel-type clutches are a combination of a rigid flywheel and clutch disc with a torsion damper, guaranteeing excellent vibration-damping and driving comfort.

To protect the gearbox, torsion dampers tuned specifically to the engine are used in the kit. The torsional vibrations generated by the engine are filtered out, noise is reduced, and the service life of the clutch is prolonged by means of low-wear clutch linings.

No special tools are required for these retrofitting kits, enabling a swift and professional conversion. New fixing bolts, high-performance grease and specialist installation instructions are enclosed.

We also supply these kits without the flywheel - SMARTFIT Conversion Service Kits, offering the benefit of the previously-installed rigid flywheel being able to be re-used when the clutch is replaced. This means that only the clutch disc, pressure plate and release bearing need to be exchanged.

SMARTFIT Self Adjusting Kits

These Blue Print SMARTFIT kits are a high-quality aftermarket alternative to a self-adjusting clutch.

Quick and easy fitment is guaranteed because conventional clutch covers are used, and no special tools are required to install them. There is no need to secure the clutch cover without applying a counterforce. This not only significantly reduces the time required, but also the risk of incorrect installation.

Special clutch linings ensure that the SMARTFIT kits enjoy a long service life, whilst meeting the customers’ demands for comfort.

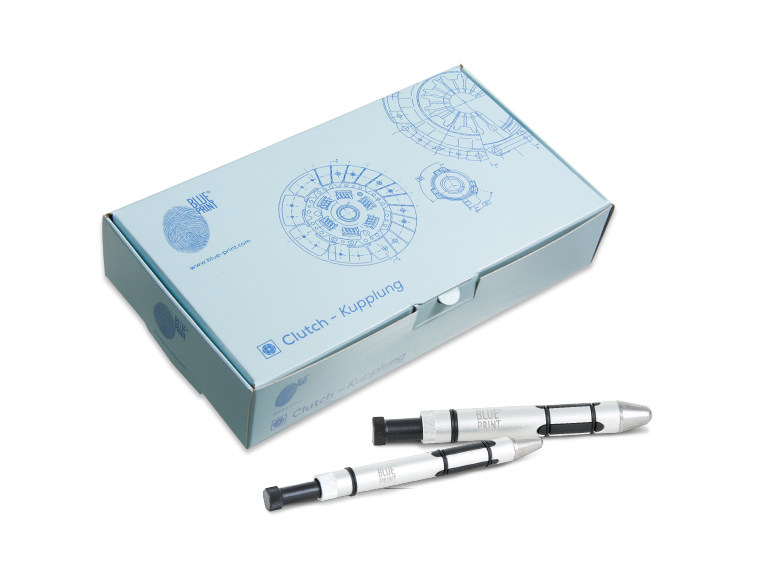

Clutch Alignment Tool

When it comes to assembling a clutch kit, this tool is perfect for quickly and accurately aligning the clutch drive plate to the flywheel pilot hole or spigot bearing.

This tool kit is supplied with two universal expanding mandrels for clutch plates 15-19mm and 20-26.6mm and is suitable for use on most passenger cars and light commercial vehicles.